Water & Soft Drinks

Manufacturing a liter of beverage generates as much as six liters of waste water. The effective management of this waste water is critical to hygiene, employee safety and production continuity. The need for high performance, hygienically designed drainage systems and the significant impact they have on food safety is widely accepted by food and beverage manufacturers. At ACO we’re committed to helping companies put hygiene first.

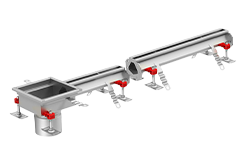

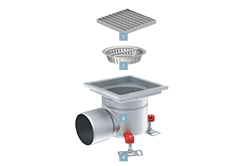

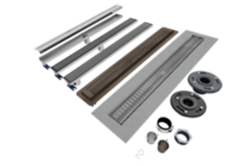

Several ACO product recommendations include: