Water & Soft Drinks

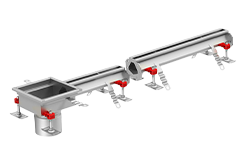

Manufacturing a liter of beverage generates as much as six liters of waste water. The effective management of this waste water is critical to hygiene, employee safety and production continuity. The need for high performance, hygienically designed drainage systems and the significant impact they have on food safety is widely accepted by food and beverage manufacturers. At ACO we’re committed to helping companies put hygiene first.

Maximum Hygiene

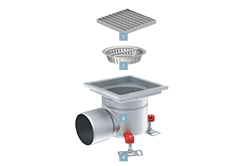

Hygiene is a top priority in a commercial kitchen. Make sure that all components of the drainage system have a round bevel. Residues can easily get stuck in corners. Prevent your drainage system from becoming a breeding ground for germs and bacteria. ACO has developed HygieneFirst® products for this area.

![]()

Safety

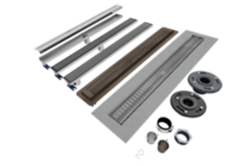

Surfaces in an industrial kitchen should be slip-resistant. This also applies to the drainage boxes, channels or drains. The drainage system should be able to drain off large amounts of water quickly to avoid puddles.

![]()

Permanent Tightness

The connection area between the floor pan or floor drain and the floor covering should be permanently tight and level. This not only ensures that the system is more durable and stable, it also reduces the risk of various occupational accidents.

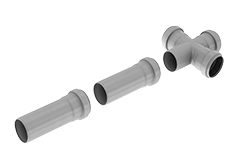

Several ACO product recommendations include: